Fefco Water resistant side seam adhesives for corrugated inliner gluing

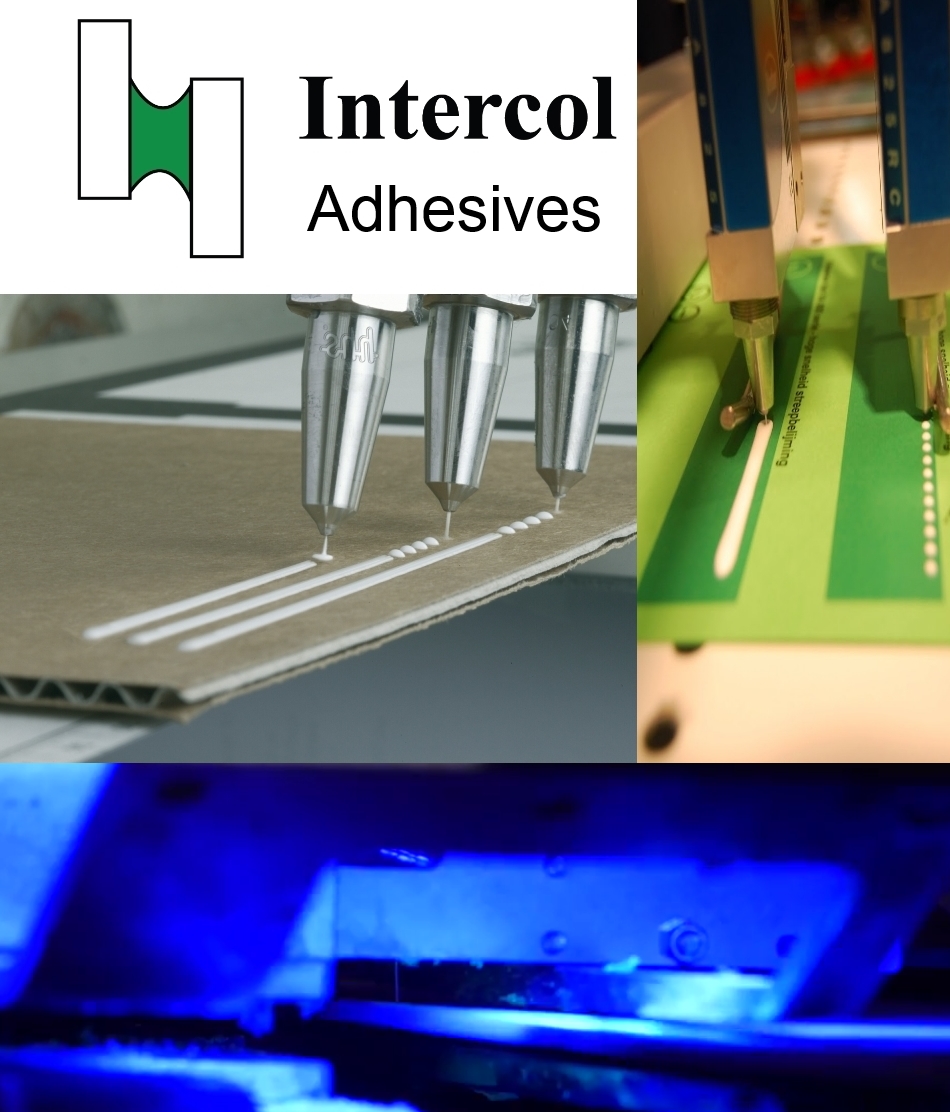

Paper adhesives professional and glue manufacturer Intercol has extensive expertise in bonding paper products, water-resistant supporting cartons, solid, folding cardboard, corrugated cardboard and honeycomb, which as a whole must meet various requirements of TAPPI and / or FEFCO such as water resistance for corrugated boxes (side seem gluing).Also laminating flat paper (withoutblisters) is a challenge that we like professionally and eagerly. Our range includes water-based adhesives on a synthetic and vegetable basis, hot glues based on gelatine and hot melt adhesives.

Corrugated Board newsletter.

Corrugated Board newsletter.

Do you work with Inliners (Martin, Bobst, Emba, Tanabe, Isowa, enz.) and are you looking for:

- Higher machine outputs

- Less uncontrolled and controlled (cleaning) stops

- More versatile adhesives for laminated, coated or water resistant applications

- More efficieny in producing cartons.

Then you should have a look at Intercol's range of Inliner adhesives.

900 series: standard range for inliner and folder gluing, fast setting

284 series: allowing longer open time for stacking

623 series: for laminated (PE/PP/PET) board quality

620 series: water resistant bond on PE/PP/PET

Although we have a standard range, some adhesives may be adapted to run optimal on your application.

The described properties above have to be confirmed for your application by our customers. As Intercol Adhesives has no influence on the used board and production circumstances.

Intercol has more than 40 years experience in industrial adhesives for the corrugated board.

1. Machines still have to go faster and faster, generating more output.

Because of changes in machinery, substrates, markets, environmental issues, food legislation and developing customer requirements factors as application knowledge, chemical innovation, the reliability and efficiency of production lines areever more crucial.

Machines have to run faster and more efficient with less machine stops and higher accurancy to meet the production and customer requirements nowadays. Only one failure on a pallet of boxes can be reason for your customers to reject the whole pallet with products. Therefore these inliner gluing machines need to be adapted to have "0" failure rate, one of the big game changing factors in inliner glueing machines is the change to non-contact glue application, in combination with food safe glue detection, even on white board that is polluted with "invisible" UV inks. On older machines still wheel or a contact-nozzle are used.

By introducing camera detection and electronic control systems instead of mechanical detection many advantages can be benefitted from, such as high speed adhesiove application, more accurate and reliable glue patterns are saving money.Therefore adhesive-system suppliers respond to this development and appropriate solutions, which are till developing together with adhesive manufacturers, to meet all the needs such as:

-water resistance

-food legislation

-machine speeds

-more advanced substrates, such as BioBased or BioDegradable, or other more ecological paper developements and alternatives.

2. Most recent dhesive Developments.

Non contact glue application systems have changed to complex integrated solutions on inliners in the corrugated board industry. These controlled adhesives appllied systems have created solutions for suppliers such as Bobst, Tannabe, Heidelberg, Vega and others to provide higher production speeds of their machines. Intercol, as adhesive manufacturer, has been involved in these efficiency-developments from the beginning and has a broad range of adhesives for non-contact (Jetting) glue application. Through collaboration with adhesive system suppliers, such as Baumer HHS, Nordson, Robatech, Valco Melton and others, machine builders and the packaging industry are well acquanted. Therefore Intercol Adhesives can guarantee that our glues are developed to provide the corrugated board industry with a reliable and improved production process.

New adhesive application equipment can be expensive, but in most cases this investment has a short payback time. The corrugated board industry has not only cost saving through higher machine speed, but also experience:

- Less adhesive usage, because of interrupted glue patterns.

- More control and consistent glue volume applied

- Better control at higher and lower (start up) machine speeds. E.g. making glue-dots at low speed, and stripes at high machine-speed.

- Easy start up after machine stops, no nozzle drying.

New dosing equipment needs new glues, Contact Intercol adhesives for:

- No stops for contamination of the nozzles, showing perfect glue patterns and no nozzle blockages.

- No spitting, Clean running, no "satelites"

- Excellent start/stop properties, even after long machine-stops

- No blockingof glue-filters

- High speed fibre bond, enabling fast packaging and palletizing at the end of the inliner.

- High wet-tack adhesive, enabling high stress load on the glue lap and no fish-tailing or release.

Due to increasing inliner speeds it's usual nowadays to ensure quality with electronic, camera guided systems,a visual inspection for glue detection. Intercol is known with several detection techniques and is still developing new detection techniques. Developments and quality checks in our laboratory ensure smooth cooperation between our adhesives and the electronic detection system. Besides purple UV-colour we have more visual possibilities, to build into our enhanced adhesive formulations

6. Right adhesive raw materials

Many packaging materials find their destination in the food related industry. In these markets are HACCP, BRC, FDA and food related EU laws strictly necessary. Adhesives need to meet many requirements, such as EU-LAW, FDA, BfR, SML, REACH, etc.. Our Adhesive Raw materials are preferably selected and engineered to meet all these requirements.

More and more plasticizers, such as the "well known" Phthalates were were seen as unwanted plasticizers. Already since 2010 Intercol replaced this plasticizer with food-approved plasticizers, and plasticizer free adhesives, to avoid any discussions on this topic, in line with our environmental goals.

Above mentioned adhesive specifications, do result in an extensive range of glues, specialized for food packagin applications in producing corrugated board boxes and other products.

For a standard adhesive solution, a customer made solution, or for any questions please contact:

Mr. Adrie Donker

Adhesive- and application specialist, Intercol BV

Mobile: +31-6-20015042

Office: +31-318-636363

Fax: +31-318 639474

Mail: Dit e-mailadres wordt beveiligd tegen spambots. JavaScript dient ingeschakeld te zijn om het te bekijken.

Web: www.intercol.nl