Hot melt adhesives are often used to attach items on a pallet that stay removable as well. Hot melt adhesives are most blends, and therefor, several meltable raw materials can be used. Hot melt adhesives can :

- Look like a plastic foil, fully transparent, non sticky

- Look like a transparent tape

- Be very sticky, like ducttape

- Cleanly and easy removable like sticky notes

- Appear like candlewax, harder and softer

Applications

- Stacking plastic bottles on a pallet

- Stacking boxes on a pallet

- Stacking bags on a pallet

Reduce stretch film

Applying a hot melt to a pallet, for example, to repackaged products is often an ideal solution to save on stretch film, pallet wrapping film and, consequently, waste. In addition, production processes become more efficient because stabilization takes place inline, the changing of rolls of film is unnecessary and less investment and space is required in production, for example for a pallet wrapper.

Reduce environmental impact

Pallet stabilization with Anti Slip Adhesives are a cost effective and environmentally friendly solution

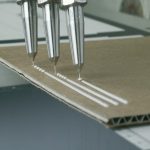

Pallet stabilization with anti-skid adhesives, especially hot melt adhesives, are applied directly to the packaging through a simple application, this method saves resources and costs. Unlike the conventional method, where intermediate cardboard layers are applied and the pallet is wrapped in plastic film.

Save on foil purchases, use less than 10% of it for anti-slip adhesive and save on waste at your customer’s site!